Page 202 - oxcatalog-2019

P. 202

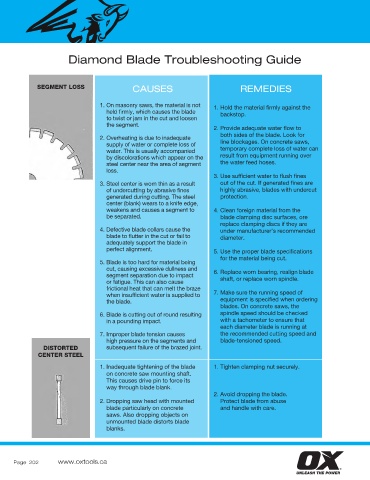

Diamond Blade Troubleshooting Guide

SEGMENT LOSS CAUSES REMEDIES

1. On masonry saws, the material is not 1. Hold the material firmly against the

held firmly, which causes the blade backstop.

to twist or jam in the cut and loosen

the segment.

2. Provide adequate water flow to

both sides of the blade. Look for

2. Overheating is due to inadequate

supply of water or complete loss of line blockages. On concrete saws,

water. This is usually accompanied temporary complete loss of water can

by discolorations which appear on the result from equipment running over

steel center near the area of segment the water feed hoses.

loss.

3. Use sufficient water to flush fines

3. Steel center is worn thin as a result out of the cut. If generated fines are

of undercutting by abrasive fines highly abrasive, blades with undercut

generated during cutting. The steel protection.

center (blank) wears to a knife edge,

weakens and causes a segment to 4. Clean foreign material from the

be separated. blade clamping disc surfaces, ore

replace clamping discs if they are

4. Defective blade collars cause the under manufacturer’s recommended

blade to flutter in the cut or fail to diameter.

adequately support the blade in

perfect alignment. 5. Use the proper blade specifications

for the material being cut.

5. Blade is too hard for material being

cut, causing excessive dullness and 6. Replace worn bearing, realign blade

segment separation due to impact shaft, or replace worn spindle.

or fatigue. This can also cause

frictional heat that can melt the braze

when insufficient water is supplied to 7. Make sure the running speed of

the blade. equipment is specified when ordering

blades. On concrete saws, the

6. Blade is cutting out of round resulting spindle speed should be checked

in a pounding impact. with a tachometer to ensure that

each diameter blade is running at

7. Improper blade tension causes the recommended cutting speed and

high pressure on the segments and blade-tensioned speed.

DISTORTED subsequent failure of the brazed joint.

CENTER STEEL

1. Inadequate tightening of the blade 1. Tighten clamping nut securely.

on concrete saw mounting shaft.

This causes drive pin to force its

way through blade blank.

2. Avoid dropping the blade.

2. Dropping saw head with mounted Protect blade from abuse

blade particularly on concrete and handle with care.

saws. Also dropping objects on

unmounted blade distorts blade

blanks.

Page 202 www.oxtools.ca