Page 205 - oxcatalog-2019

P. 205

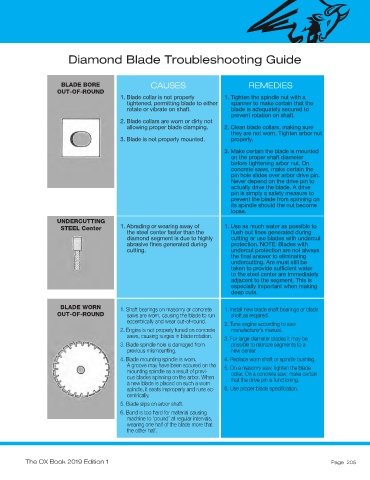

Diamond Blade Troubleshooting Guide

BLADE BORE CAUSES REMEDIES

OUT-OF-ROUND

1. Blade collar is not properly 1. Tighten the spindle nut with a

tightened, permitting blade to either spanner to make certain that the

rotate or vibrate on shaft. blade is adequately secured to

prevent rotation on shaft.

2. Blade collars are worn or dirty not

allowing proper blade clamping. 2. Clean blade collars, making sure

they are not worn. Tighten arbor nut

3. Blade is not properly mounted. properly.

3. Make certain the blade is mounted

on the proper shaft diameter

before tightening arbor nut. On

concrete saws, make certain the

pin hole slides over arbor drive pin.

Never depend on the drive pin to

actually drive the blade. A drive

pin is simply a safety measure to

prevent the blade from spinning on

its spindle should the nut become

loose.

UNDERCUTTING

STEEL Center 1. Abrading or wearing away of 1. Use as much water as possible to

the steel center faster than the flush out fines generated during

diamond segment is due to highly cutting or use blades with undercut

abrasive fines generated during protection. NOTE: Blades with

cutting. undercut protection are not always

the final answer to eliminating

undercutting. Are must still be

taken to provide sufficient water

to the steel center are immediately

adjacent to the segment. This is

especially important when making

deep cuts.

BLADE WORN 1. Shaft bearings on masonry or concrete 1. Install new blade shaft bearings or blade

OUT-OF-ROUND saws are worn, causing the blade to run shaft,as required.

eccentrically and wear out-of-round. 2. Tune engine according to saw

2. Engine is not properly tuned on concrete manufacturer’s manual.

saws, causing surges in blade rotation. 3. For large diameter blades it may be

3. Blade spindle hole is damaged from possible to rebraze segments to a

previous mismounting. new center.

4. Blade mounting spindle is worn. 4. Replace worn shaft or spindle bushing.

A groove may have been scoured on the 5. On a masonry saw, tighten the blade

mounting spindle as a result of previ- collar. On a concrete saw, make certain

ous blades spinning on the arbor. When that the drive pin is functioning.

a new blade is placed on such a worn

spindle, it seats improperly and runs ec- 6. Use proper blade specification.

centrically.

5. Blade slips on arbor shaft.

6. Bond is too hard for material causing

machine to ‘pound’ at regular intervals,

wearing one half of the blade more that

the other half.

The OX Book 2019 Edition 1 Page 205