Page 203 - oxcatalog-2019

P. 203

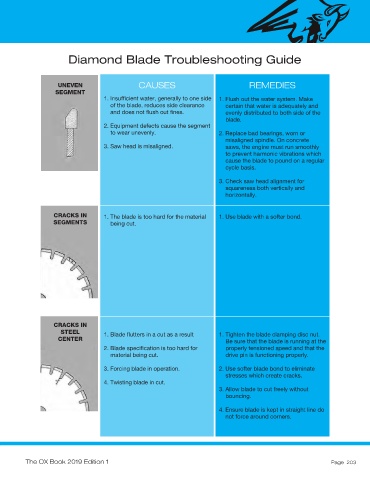

Diamond Blade Troubleshooting Guide

UNEVEN CAUSES REMEDIES

SEGMENT

1. Insufficient water, generally to one side 1. Flush out the water system. Make

of the blade, reduces side clearance certain that water is adequately and

and does not flush out fines. evenly distributed to both side of the

blade.

2. Equipment defects cause the segment

to wear unevenly. 2. Replace bad bearings, worn or

misaligned spindle. On concrete

3. Saw head is misaligned. saws, the engine must run smoothly

to prevent harmonic vibrations which

cause the blade to pound on a regular

cycle basis.

3. Check saw head alignment for

squareness both vertically and

horizontally.

CRACKS IN 1. The blade is too hard for the material 1. Use blade with a softer bond.

SEGMENTS being cut.

CRACKS IN

STEEL 1. Blade flutters in a cut as a result 1. Tighten the blade clamping disc nut.

CENTER Be sure that the blade is running at the

2. Blade specification is too hard for properly tensioned speed and that the

material being cut. drive pin is functioning properly.

3. Forcing blade in operation. 2. Use softer blade bond to eliminate

stresses which create cracks.

4. Twisting blade in cut.

3. Allow blade to cut freely without

bouncing.

4. Ensure blade is kept in straight line do

not force around corners.

The OX Book 2019 Edition 1 Page 203