Page 206 - oxcatalog-2019

P. 206

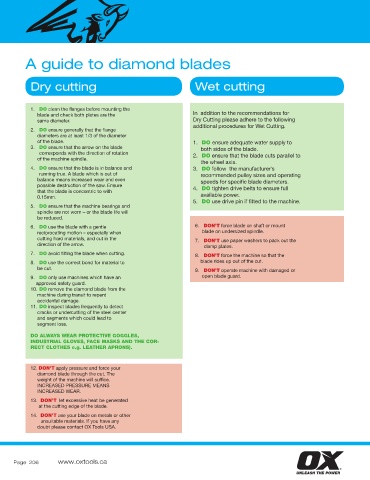

A guide to diamond blades

Dry cutting Wet cutting

1. DO clean the flanges before mounting the

blade and check both plates are the In addition to the recommendations for

same diameter. Dry Cutting please adhere to the following

additional procedures for Wet Cutting.

2. DO ensure generally that the flange

diameters are at least 1/3 of the diameter

of the blade. 1. DO ensure adequate water supply to

3. DO ensure that the arrow on the blade both sides of the blade.

corresponds with the direction of rotation 2. DO ensure that the blade cuts parallel to

of the machine spindle.

the wheel axis.

4. DO ensure that the blade is in balance and 3. DO follow the manufacturer’s

running true. A blade which is out of recommended pulley sizes and operating

balance means increased wear and even speeds for specific blade diameters.

possible destruction of the saw. Ensure 4. DO tighten drive belts to ensure full

that the blade is concentric to with

0.15mm. available power.

5. DO use drive pin if fitted to the machine.

5. DO ensure that the machine bearings and

spindle are not worn – or the blade life will

be reduced.

6. DO use the blade with a gentle 6. DON’T force blade on shaft or mount

reciprocating motion – especially when blade on undersized spindle.

cutting hard materials, and cut in the 7. DON’T use paper washers to pack out the

direction of the arrow. clamp plates.

7. DO avoid tilting the blade when cutting. 8. DON’T force the machine so that the

8. DO use the correct bond for material to blade rides up out of the cut.

be cut. 9. DON’T operate machine with damaged or

9. DO only use machines which have an open blade guard.

approved safety guard.

10. DO remove the diamond blade from the

machine during transit to repent

accidental damage.

11. DO inspect blades frequently to detect

cracks or undercutting of the steel center

and segments which could lead to

segment loss.

DO ALWAYS WEAR PROTECTIVE GOGGLES,

INDUSTRIAL GLOVES, FACE MASKS AND THE COR-

RECT CLOTHES e.g. LEATHER APRONS).

12. DON’T apply pressure and force your

diamond blade through the cut. The

weight of the machine will suffice.

INCREASED PRESSURE MEANS

INCREASED WEAR.

13. DON’T let excessive heat be generated

at the cutting edge of the blade.

14. DON’T use your blade on metals or other

unsuitable materials. If you have any

doubt please contact OX Tools USA.

Page 206 www.oxtools.ca