Page 204 - oxcatalog-2019

P. 204

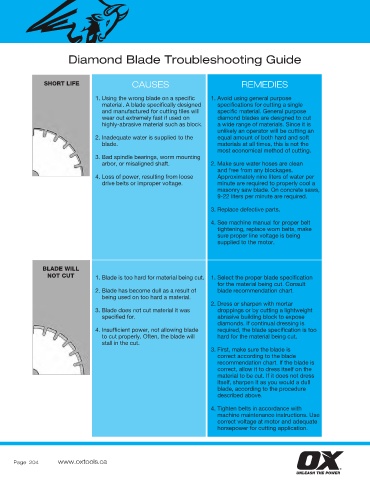

Diamond Blade Troubleshooting Guide

SHORT LIFE CAUSES REMEDIES

1. Using the wrong blade on a specific 1. Avoid using general purpose

material. A blade specifically designed specifications for cutting a single

and manufactured for cutting tiles will specific material. General purpose

wear out extremely fast if used on diamond blades are designed to cut

highly-abrasive material such as block. a wide range of materials. Since it is

unlikely an operator will be cutting an

2. Inadequate water is supplied to the equal amount of both hard and soft

blade. materials at all times, this is not the

most economical method of cutting.

3. Bad spindle bearings, worm mounting

arbor, or misaligned shaft. 2. Make sure water hoses are clean

and free from any blockages.

4. Loss of power, resulting from loose Approximately nine liters of water per

drive belts or improper voltage. minute are required to properly cool a

masonry saw blade. On concrete saws,

9-22 liters per minute are required.

3. Replace defective parts.

4. See machine manual for proper belt

tightening, replace worn belts, make

sure proper line voltage is being

supplied to the motor.

BLADE WILL

NOT CUT 1. Blade is too hard for material being cut. 1. Select the proper blade specification

for the material being cut. Consult

2. Blade has become dull as a result of blade recommendation chart.

being used on too hard a material.

2. Dress or sharpen with mortar

3. Blade does not cut material it was droppings or by cutting a lightweight

specified for. abrasive building block to expose

diamonds. If continual dressing is

4. Insufficient power, not allowing blade required, the blade specification is too

to cut properly. Often, the blade will hard for the material being cut.

stall in the cut.

3. First, make sure the blade is

correct according to the blade

recommendation chart. If the blade is

correct, allow it to dress itself on the

material to be cut. If it does not dress

itself, sharpen it as you would a dull

blade, according to the procedure

described above.

4. Tighten belts in accordance with

machine maintenance instructions. Use

correct voltage at motor and adequate

horsepower for cutting application.

Page 204 www.oxtools.ca